Mattress manufacturing is a precise process and we’ve worked hard to refine ours with the help of our resident experts! Carefully assembled in Yorkshire, we use a combination of state-of-the-art mattress machinery and the artisan expertise of our herdysleep craftsmen (find out about them here). Keep reading to find out how we get our mattresses so snuggly.

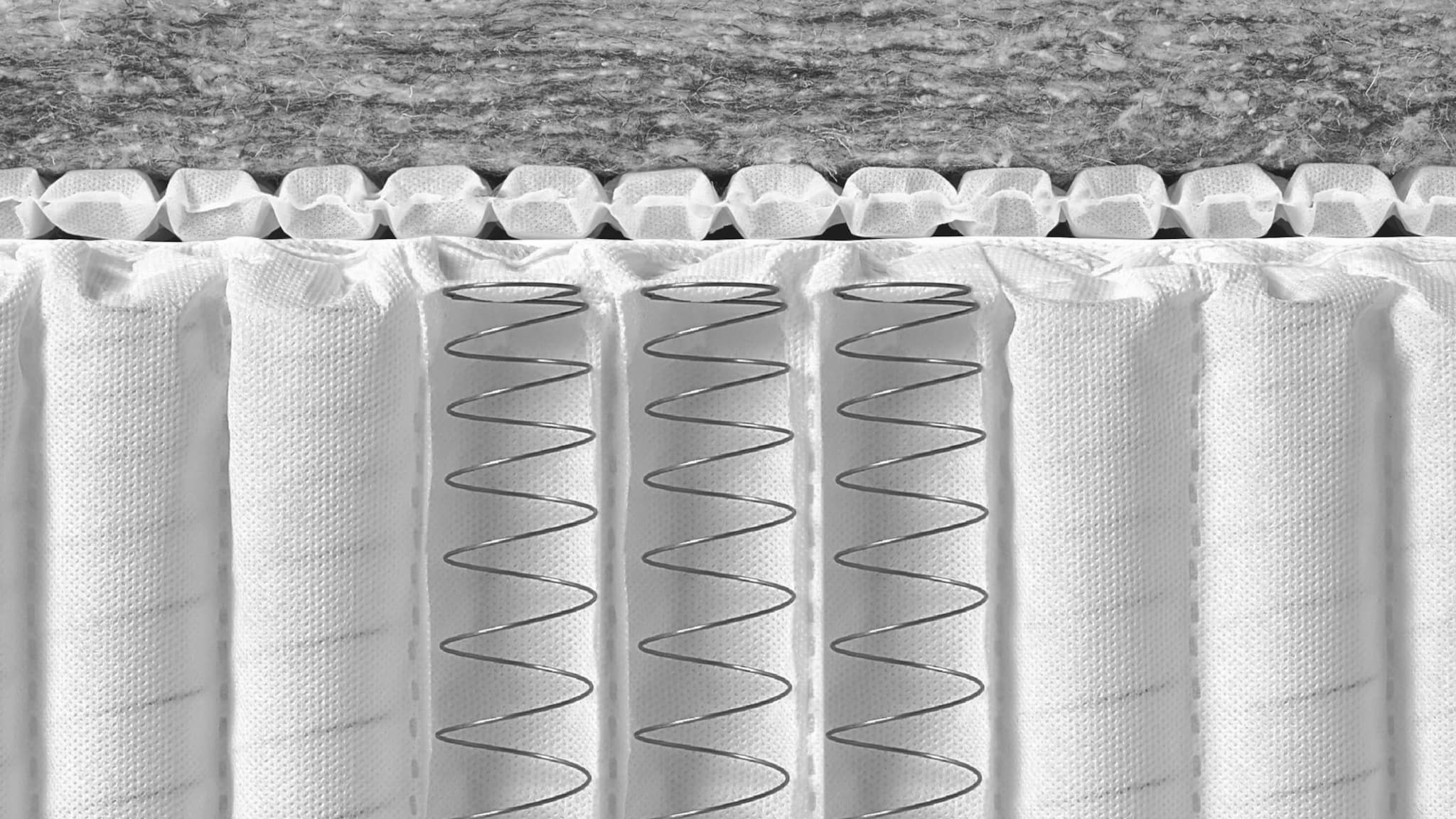

This is where the individual layers of the Herdysleep mattress are assembled. The mattress is actually built upside down, starting with the tiny comfort springs and then the Cortec™ core of the mattress; this makes up the foundations of our mattress.

Attaching the border

In the next step, the mattress border is attached to the core to provide structure and ensure it is secured in place, giving the mattress its shape. The natural wool and cashmere fillings are then layered on top of the pocket springs before being covered with the mattress fabric, ready to be tufted.

Tufting

Tufting is a traditional mattress manufacturing method but here at Herdysleep we tuft-by-hand to ensure the best possible finish.

Tufting itself is the act of securing the layers of pocket springs and natural fillings in place. The mattress is first compressed in a machine as tufting tape is placed within a groove on the tufting needle. The needle is then driven through the mattress at regular intervals; a process which secures all the layers in place. Our craftsmen make their way around both sides of the mattress, covering the ends of the tufting tape with a pompom to make sure nothing can move out of place.

The mattress is then released from the machine allowing it to expand, providing a luxuriously domed sleeping surface. We’re now ready to go into the final stage of assembly – our wool mattress is almost complete!

Tape edging

The last stage in the mattress assembly process, this is a highly skilled procedure whereby our craftsmen use a tape edging machine (rather like a large sewing machine) to attach the chemical-free sleeping surface to the mattress borders. This ensures the comfort layers are locked within the mattress and keeps everything in place.

Finally, our Herdysleep mattress is wrapped up and ready to go!

Anything else ewe'd like to know?

That completes the manufacturing process of the Herdysleep mattress! Interested in finding out more? Please do give us a call or join the flock on our Facebook, Twitter, or Instagram – we’d love to hear from ewe!

Next up we’ll be sharing detailed biographies of all of our Herdysleep craftsmen so you can meet the faces behind the mattress!